FLEXIBLE GEAR COUPLING

Aries Industries are distinguised by their MECHANICAL FLEXIBILITY and compensation of MISALIGNMENT of the connected shafts automatically without any loss of transmitted power during running. These coupling ensure greater flexibility because of their well designed tooth formation generated by INVOLUTE system to ensure uniform toothe PROFILE AND PITCH.

LUBRICATION

The coupling must be fitted with grease or oil. It is recommended to use grease where the maximum temperature is within 800C & for temperature above 800C oil should be use.

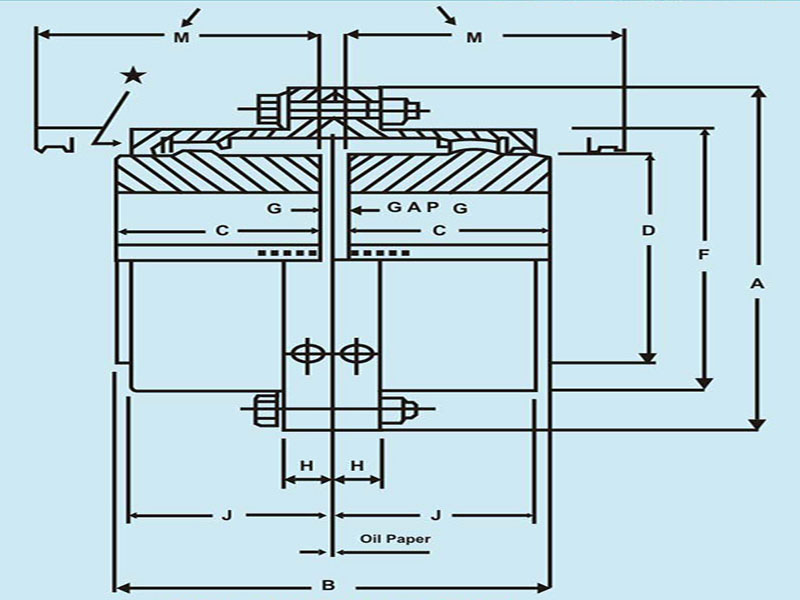

| COMMON FOR BOTH COUPLING | FULL FLEXIBLE TYPE | HALF FLEXIBLE TYPE | ||||||||||||||||||||

| Gear Coupling NO. | H.P. Capacity AT 100 R.P.M. | Max. TORQUE Kg. M. | Max R.P.M. | Bore Min. | A | C | D | F | M | G | H | Bore MAX. | J | B | WR² Kgm² | Wt.In Kg | K | Q | Bore Max. | F1 | WR² Kgm² | Wt. in Kg |

| KCI 100 | 7 | 50 | 8000 | 10 | 120 | 45 | 50 | 75 | 55 | 1.5 | 15 | 30 | 39.5 | 93 | 0.03 | 4 | 93 | 46.5 | 50 | 70 | 0.03 | 4 |

| KCI 101 | 14 | 100 | 6300 | 20 | 170 | 55 | 65 | 110 | 65 | 2.5 | 17 | 40 | 49 | 115 | 0.14 | 10 | 115 | 57.5 | 60 | 85 | 0.15 | 10 |

| KCI 102 | 35 | 250 | 5000 | 30 | 185 | 70 | 85 | 125 | 80 | 2.5 | 17 | 55 | 62 | 145 | 0.20 | 15 | 145 | 72.5 | 75 | 110 | 0.24 | 15 |

| KCI 103 | 63 | 450 | 4000 | 40 | 220 | 85 | 105 | 150 | 105 | 2.5 | 20 | 70 | 78 | 175 | 0.48 | 25 | 175 | 87.5 | 90 | 130 | 0.51 | 25 |

| KCI 104 | 119 | 850 | 3350 | 50 | 250 | 105 | 130 | 175 | 125 | 2.5 | 20 | 85 | 96 | 215 | 0.95 | 39 | 215 | 107.5 | 110 | 160 | 1.0 | 40 |

| KCI 105 | 182 | 1300 | 2800 | 60 | 290 | 110 | 155 | 200 | 140 | 5 | 25 | 105 | 106 | 230 | 1.90 | 59 | 230 | 115 | 130 | 185 | 2.0 | 60 |

| KCI 106 | 280 | 2000 | 2500 | 75 | 320 | 125 | 175 | 230 | 155 | 5 | 25 | 120 | 117 | 260 | 3.00 | 85 | 260 | 130 | 150 | 215 | 3.3 | 85 |

| KCI 107 | 490 | 3500 | 2100 | 90 | 350 | 140 | 205 | 260 | 175 | 5 | 25 | 130 | 134 | 290 | 5.25 | 103 | 290 | 145 | 170 | 240 | 5.8 | 106 |

| KCI 108 | 630 | 4500 | 1900 | 105 | 380 | 155 | 230 | 290 | 190 | 5 | 25 | 150 | 147 | 320 | 8.50 | 138 | 320 | 160 | 200 | 285 | 9.5 | 149 |

| KCI 109 | 784 | 5600 | 1700 | 125 | 430 | 165 | 250 | 330 | 205 | 5 | 25 | 170 | 156 | 340 | 15.00 | 210 | 340 | 170 | 220 | 315 | 16.8 | 200 |

| KCI 110 | 1148 | 8200 | 1400 | 140 | 490 | 180 | 310 | 390 | 220 | 5 | 25 | 210 | 171 | 370 | 30.50 | 277 | 370 | 185 | 260 | 370 | 35.0 | 274 |

| KCI 111 | 1536 | 11000 | 1250 | 160 | 545 | 200 | 350 | 445 | 240 | 5 | 30 | 260 | 192 | 410 | 58 | 550 | ||||||

| KCI 112 | 2053 | 14700 | 1120 | 180 | 590 | 240 | 400 | 490 | 280 | 5 | 30 | 300 | 231 | 490 | 88 | 710 | ||||||

| KCI 113 | 2793 | 20000 | 1000 | 200 | 680 | 260 | 440 | 555 | 310 | 7.5 | 35 | 330 | 242 | 535 | 138 | 980 | ||||||

| KCI 114 | 3994 | 28600 | 900 | 220 | 730 | 280 | 500 | 610 | 330 | 7.5 | 35 | 370 | 266 | 575 | 291 | 1320 | ||||||

| KCI 115 | 4852 | 34750 | 800 | 250 | 780 | 320 | 540 | 660 | 370 | 7.5 | 35 | 410 | 305 | 665 | 353 | 1700 | ||||||

| KCI 116 | 8378 | 60000 | 710 | 300 | 900 | 350 | 625 | 755 | 425 | 10.0 | 45 | 455 | 335 | 720 | 680 | 2550 | ||||||

| KCI 117 | 11917 | 83550 | 630 | 375 | 1000 | 400 | 720 | 855 | 460 | 10.0 | 45 | 520 | 386 | 820 | 1235 | 3620 | ||||||

| KCI 118 | 15778 | 113000 | 560 | 450 | 1100 | 450 | 810 | 950 | 510 | 10.0 | 55 | 610 | 430 | 920 | 1965 | 4860 | ||||||

| KCI 119 | 20805 | 149000 | 500 | 520 | 1250 | 485 | 910 | 1050 | 560 | 15.0 | 55 | 710 | 446 | 1000 | 3012 | 6380 | ||||||

NOTE:-

1.Made to order/special Gear Couplings also can be manufactured

2.Dynamic balancing & Heat Treatment Will be done on request.(Extra)