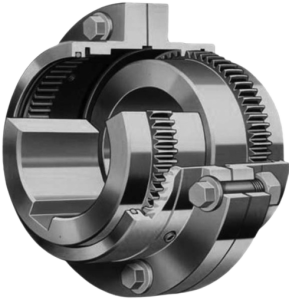

Half Gear Coupling- Details.

Type: Gear Type

Size: 100 to 107

Material: EN19/En24/C45/Stainless Steel

Usage/Application: Industrial

Brand: Aries

Color: Black or Silver

Surface Treatment: If required Harden

Shape: Round

What is half gear coupling? Half gear coupling – A half gear coupling has a stiff hub on the driver shaft, a grooved hub on the driven shaft, and an internal geared sleeve. The driven shaft’s sleeve is fastened to the stiff hub with bolts.

We provide a full selection of gear couplings, spindle couplings, and gear couplings for torsional shafts.

We provide a full selection of gear couplings, spindle couplings, and gear couplings for torsional shafts.

To achieve a longer life, the couplings are made from high grade material that has been appropriately toughened and tempered.

These couplings are widely used in thermal power plants, paper factories, rubber, sugar, and steel industries, as well as in cranes, conveyors, rolling mills, and other equipment.

Half gear coupling – A half gear coupling has a stiff hub on the driving shaft and a toothed hub and internal geared sleeve on the driven shaft.

The driven shaft’s sleeve is fastened to the stiff hub with bolts.

The ends of the hub teeth will wear down under strong loads, causing excessive play between the hub and sleeve. The coupling’s lifespan is shortened as a result.

Aries Triple Crowned Teeth

A completely mechanized hobbing machine with an integrated crowing attachment that is managed by hydraulic and electronic technologies is used to create the triple-crowned teeth hub. Due to the curved teeth flanks, there is a larger contact area when two shafts on the apparatus are out of alignment. This indicates that the coupling’s life has increased.

A half gear coupling has a stiff hub on the driver shaft, a toothed hub on the driven shaft, and an internal geared sleeve. The driven shaft’s sleeve is fastened to the stiff hub with bolts.

Aries Industries has been providing the market with cutting-edge and contemporary engineering machine shops since 2012. We are able to do extremely precise work in accordance with client requests. Our most up-to-date equipment and highly qualified workforce can satisfy industrial requirements in every way. For Inquiries please call: +91-9974245380 & visit www.industruialgearpoint.com